What Is Industrial Adhesive?

Industrial adhesives are high-strength bonding agents designed for use in manufacturing, construction, automotive, and various other industries. These adhesives provide durable, long-lasting bonds, often replacing traditional mechanical fastening methods like bolts and welding. As a result, they improve production efficiency, reduce weight, and enhance product durability.

What Are Industrial Adhesives Made Out Of?

Industrial adhesives are formulated from a variety of chemical bases, each offering unique properties. The most common types include:

- Water-Based Adhesives

Water-based adhesives use water as the solvent or carrier. Once the water evaporates, the adhesive forms a bond. These adhesives are environmentally friendly and often used in paper, packaging, and woodworking industries. However, they are less effective in high-humidity environments or where water resistance is needed. - Solvent-Based Adhesives

Solvent-based adhesives contain organic solvents, which evaporate during curing, leaving behind a strong bond. These adhesives offer higher performance in extreme conditions, making them ideal for applications requiring heat and chemical resistance. For instance, products like SHREECRYL SS-505 (a solvent-based acrylic adhesive) excel in laminating surfaces and bonding various materials with high durability. - Hot Melt Adhesives

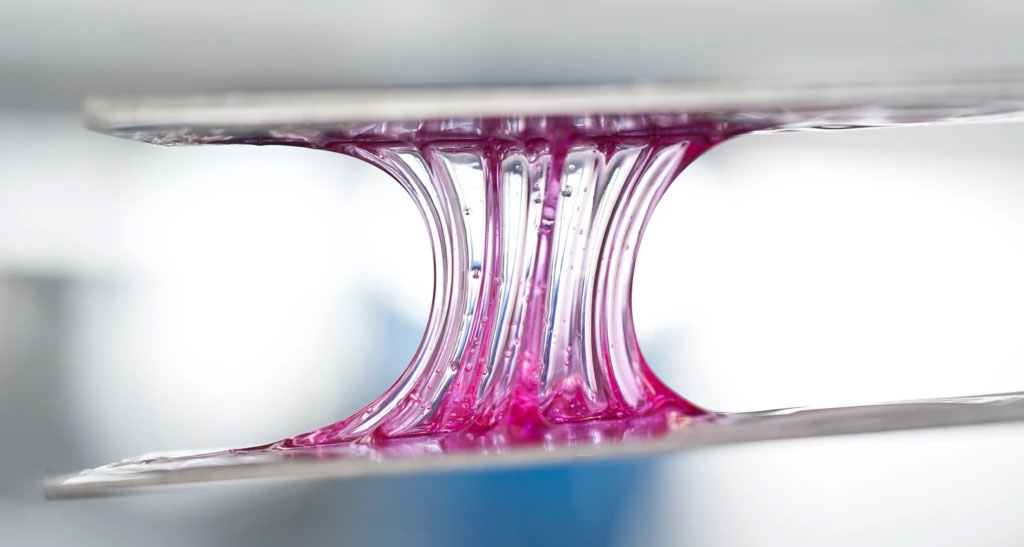

Hot melt adhesives are thermoplastics applied in a molten state and solidify as they cool. They are fast-setting and used in industries like packaging, bookbinding, and automotive. - Reactive AdhesivesReactive adhesives undergo chemical reactions during curing. They form incredibly strong bonds and are used for heavy-duty applications in aerospace, electronics, and automotive sectors.

What Can an Industrial Adhesive Be Used To Bond?

Industrial adhesives can bond an array of materials, including:

- Metals: Steel, aluminum, brass

- Plastics: PVC, ABS, polycarbonate

- Composites: Fiberglass, carbon fiber

- Wood: Hardwood, softwood, plywood

- Ceramics: Tiles, glass, porcelain

- Foam and Rubber: For insulation and automotive components

What Industries Make Use of Industrial Adhesives?

Industrial adhesives find applications in a wide range of industries, such as:

- Automotive: Used for bonding metal and plastic components, reducing vehicle weight.

- Construction: For attaching drywall, flooring, and other building materials.

- Electronics: To bond components in devices like smartphones, computers, and circuit boards.

- Packaging: Used to seal boxes, attach labels, and form durable packaging.

- Aerospace: For lightweight bonding in aircraft components to enhance fuel efficiency.

- Woodworking and Furniture Manufacturing: To assemble furniture pieces and apply veneers.

What Are The Properties of Industrial Adhesives?

Industrial adhesives come with unique properties, depending on their formulation:

- Strength: High tensile and shear strength suitable for heavy-duty applications.

- Heat Resistance: Can withstand high temperatures without losing bond integrity.

- Chemical Resistance: Resists degradation from oils, acids, and solvents.

- Flexibility: Maintains flexibility, preventing cracks in bonded materials under stress.

- Durability: Designed for long-lasting performance, even under harsh conditions.

- UV Resistance: Some adhesives resist yellowing and deterioration when exposed to sunlight.

How Long Does Industrial Adhesive Take To Dry?

The drying time of industrial adhesives varies based on the type:

- Water-Based Adhesives: Usually dry in 1-3 hours.

- Solvent-Based Adhesives: Can take 2-24 hours depending on environmental conditions.

- Hot Melt Adhesives: Solidify within seconds as they cool.

- Reactive Adhesives: May take up to 24 hours or more, depending on the curing process.

It’s important to follow the manufacturer’s guidelines for optimal drying and curing times to ensure strong bonding.

FAQ

- What is industrial adhesive used for?

Industrial adhesives are used to bond materials such as metals, plastics, wood, and composites in industries like automotive, construction, electronics, and packaging. - What are the types of industrial adhesives?

Common types include water-based, solvent-based, hot melt, and reactive adhesives, each offering specific advantages for various bonding applications. - How long does industrial adhesive take to dry?

The drying time varies depending on the type of adhesive, ranging from a few seconds for hot melt adhesives to up to 24 hours for solvent and reactive adhesives. - Are industrial adhesives environmentally friendly?

Water-based adhesives are generally more environmentally friendly, while solvent-based adhesives may require careful handling due to volatile organic compounds (VOCs). - Can industrial adhesives withstand high temperatures?

Yes, many industrial adhesives are designed to withstand extreme temperatures, making them suitable for applications in aerospace, automotive, and electronics.